The ibW jet stream mixer is the optimal link between high-frequency rotor-stator systems and the classic DIN agitators.

QUALITY / TECHNICAL CHARACTERISTICS:

- high circulation capacity

- no build-ups of eddies

- Air entry into the medium is avoided

- kurze Misch- und Prozesszeit

- short mixing and processing time

- high profitability

- open and closed versions (shaft tube) are available

- available as a jet-stream suction mixer, to suck powder dust-free

- can be installed from above, from the side or from below

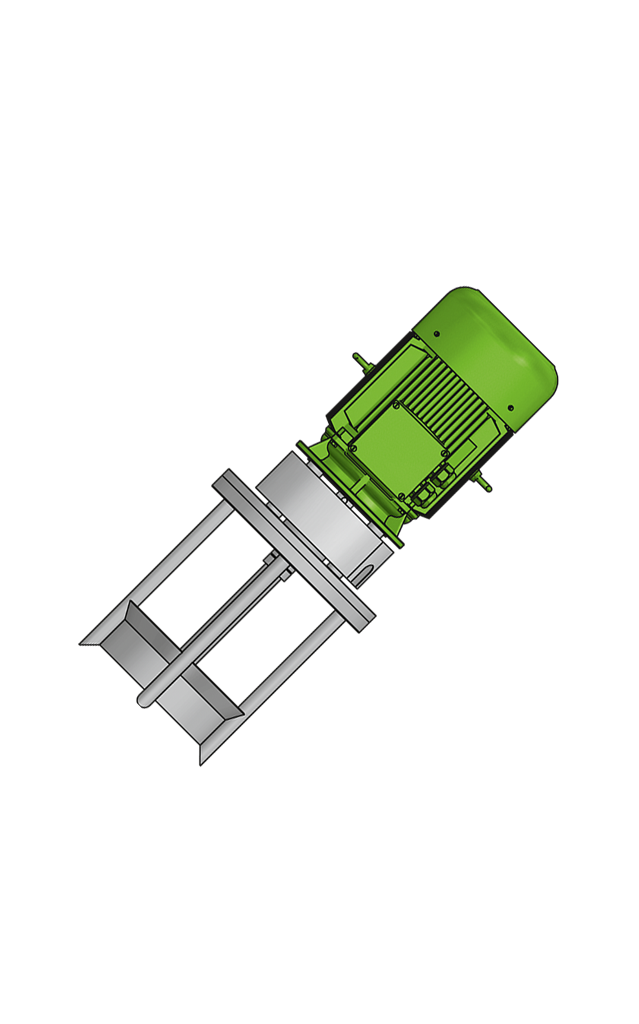

Type RRS-220

JET-STREAM SUCTION MIXER

Application areas

- To dissolve

- Mix

- Homogenize

- Gas

(Improvement of the mass transfer between the gas / liquid phase by increasing the phase-related mass transfer area)

- Suspend

(Mixing of insoluble solids in liquids)

Self-cleaning

Jetstream mixer type RotoRex with patented self-cleaning in the CIP process. For this purpose, the CIP medium (cleaning medium) is passed through the nozzle on the jet mixer. Through the special nozzles, the entire surface of the seal, shaft, propeller and turbine is reached and cleaned. Buildup, gumming-up of the mechanical seal, no contamination and carrying-off of the product.

MIXING PRINCIPLE

The high revolution velocities and close distances between rotor and turbine prevent backflow losses. A square aspect ratio in the cylindrical part ensures the high fluid thrust. The inlet and outlet angles on the turbine have different diameters, resulting in a good degree of filling and a highly directed liquid jet. On the other hand, it creates, in that small space in the mixing head, the exact turbulence that is required for simultaneous micro-mixing.

This micro-turbulence is immediately carried with the total homogeneous circulation into each zone of the mixing vessel.

The guide jet directed downwards from the rotor and turbine divides at the bottom of the vessel and creates an upward flow on the outside wall. At the liquid’s top surface, the direction of flow is reversed again to the tank center. This results in a pronounced circulation of the entire liquid in a short time, whereby critical container locations are also detected.